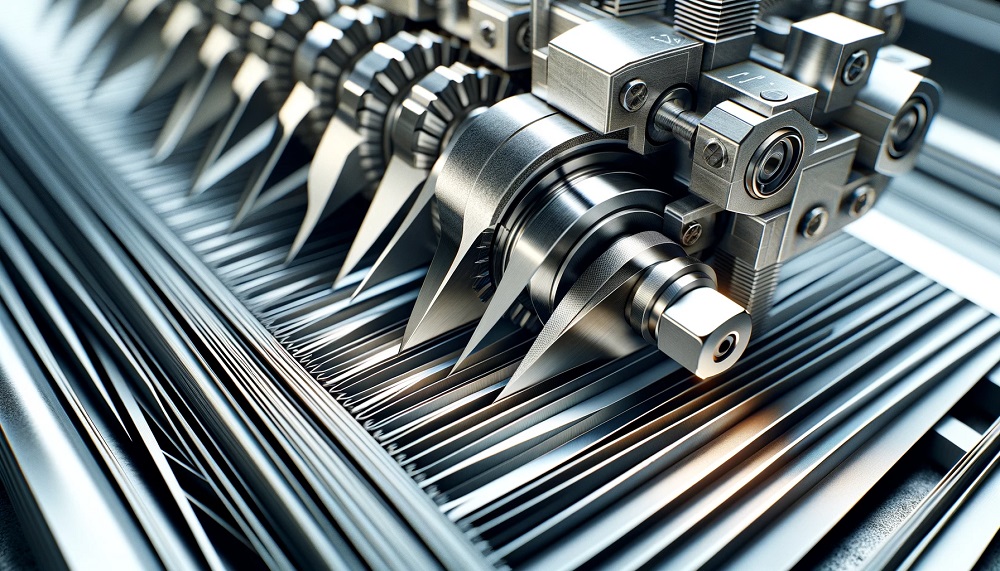

Die cutting is widely used in packaging, printing, and metalworking industries. It helps in shearing, cutting and shaping sheets into different designs and shapes. This cutting method allows the manufacturer to produce a variety of products, any identical size and body, quickly.

Precision die-cutting is a highly efficient production method. It saves time and money, boosts productivity, and delivers consistently accurate results for products ranging from tiny washers to enormous gaskets. Die-cutting machines are constantly fed nonmetallic materials and produce precision components.

Industrial die-cutters have found extensive use in the packaging sector of production. However, modern advances in technology have led to more precise die-cutting equipment. Die Cutter Blades are now used in various industries, including the automotive and medical device sectors.

What Is Die Cutting?

A “die,” or dedicated cutting tool, is the first step in the die-cutting process. Think of a cookie cutter, and you know what a die does to metal or other materials. The die removes the matrix, or extra material, on the label before it is snipped off. In proofs, the ‘die line’ is a thick coloured line that indicates the boundary of the area from which the die will be cut.

Each of the several die-cutting methods has its advantages and uses. When designing labels, you have three main options: flatbed, rotary, and semi-rotary die cutting.

Advantages Of Precision Die Cutting

Precision die cutting is quick, reliable, and economical for parts ranging from tiny washers to massive gaskets. Die Cutter Blades are constantly fed nonmetallic materials and produce precision components. Even in higher quantities, the precision of these die-cut components remains good. Details like punched holes with defined radii are possible in dozens to millions of production cycles. Pressure-sensitive adhesives (PSAs) for peel-and-stick components are one-way. Interstate combines accurate die-cutting with specialised handling and conversion.

Precision And Die Selection Machining A Die

- Precision die-cutting methods can vary, but they share a few commonalities.

- The die, a metal instrument used for die-cutting and -punching

- The composition of the gasket, which may include plastic, elastomer, film, or membrane

- The press, die-cutting machine, or other similar device.

- CNC machines, which are capable of running sophisticated design programmes

Hints For Cutting Dies

If you want to keep the matrix intact after die cutting, steer clear of angles and corners that could cause damage.

- Allow sufficient space between the hole and label edge when using a brand spot.

- Extend label artwork by at least 1/16 inch beyond the edges. This prevents accidental blank spots.

- Ensure accurate line drawing for shapes in Adobe Illustrator. Separate the die line from the background and colour it differently.

Conclusion

Die Cutter Blades have come a long way, from their manual cutting ancestors to the cutting machines of today. Their many mechanics make them adaptable enough for cutting everything from delicate tissue paper to different types of metal.